One of the most interesting books written about pumps is the 1911 book by Arthur M. Greene entitled, Pumping Machinery. It includes an interesting history of the development of pumps from the ubiquitous Shadoof and Noria devices to the present day centrifugal pump. Click to download: Pumping Machinery.

The drawing to the right shows a pump from the 1500’s with an ingenious arrangement incorporating a check valve and rotary valve.

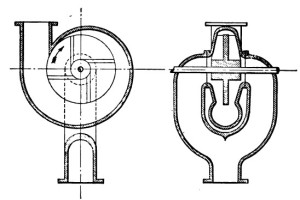

Circa 1840, the curved vane impeller made its appearance giving us the design we are so familiar with today. A pump known as the “Boston Pump”, shown below right, included a straight vaned impeller and volute design.

In Mr. Greene’s book, it is fascinating to see the degree to which pump development had already advanced–especially to see the development of mathematical equations to advance the science of hydrodynamics.

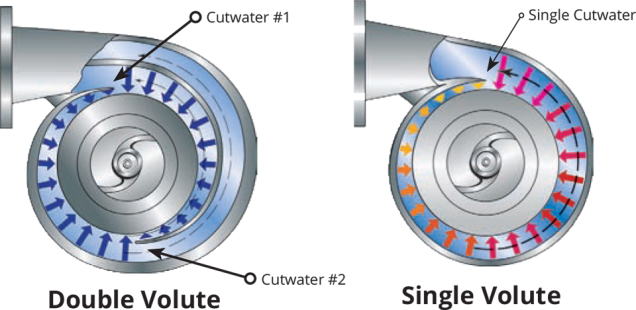

Now back to the volute. The purpose of the volute could be described as two-fold: (1) to allow additional flow to exit the impeller around the whole 360 degree circumference and (2) to enable the conversion of the kinetic energy imparted to the fluid by the impeller to pressure energy (force) to create flow.

As long as the system allows the pump to pump at the BEP (best efficiency point) then there is an orderly transition of the fluid from the impeller through the volute and into the discharge nozzle of the pump. A disorderly (or off-design) flow would be one in which the pump encounters increased or decreased pressure at the discharge nozzle. In other words, there is a state at which, based on the speed and geometry of the pump, the pump reaches a peak state of efficiency or equilibrium of these pressure states. Off-design conditions often leads to progressive damage to the pump beginning at the sealing area and eventually causing bearing failure and/or structural damage to the pump.

There are ways to improve this transition from the impeller to the discharge of the pump by using diffusers or a split tongue design, but over the years most users have chosen the lower cost of the volute design over more complex and expensive designs which would function more efficiently and reliably in off-design conditions.

Links:

- McNally Institute: Double Volute Pump

- Defining the Basics: Volutes & Impellers

- WaterWorld: The Pros & Cons of Various Centrifugal Pump Casing Types

- Diffuser vs. Volute