The essential function of oil is that of keeping moving elements separated. The amazing feature of oil is how it does this by its capacity to increase in viscosity under heavy load conditions. This is called elastohydrodynamic lubrication and it happens when the rolling element and mating surface (ball and race) elastically deform to enlarge the contact area. In what is known as the Hertzian Zone, high pressures (up to 500,000 psi) momentarily turn oil into a solid.

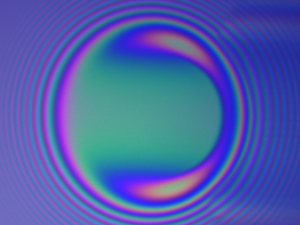

Oil film thickness in this Hertzian zone is typically less than 1 micron. A micron is 1/25th of .001 inches or 1 millionth of a meter–invisibly thin. Here is an image showing pressure zones in elastohydrodynamic (EHL) lubrication.  These pressure zones occur in rolling bearings, gears at the pitchline, sprockets at the tooth and chain contact area, and on cam lobes and followers.

These pressure zones occur in rolling bearings, gears at the pitchline, sprockets at the tooth and chain contact area, and on cam lobes and followers.

The correct viscosity of the oil is essential to creating and maintaining EHL and a fine line exists between too much or not enough viscosity. Because we generally operate in real-world conditions, the viscosity of choice MUST account for these conditions. Heat, load, vibration, misalignment and moisture all contribute to break down of the EHL fluid film layer. Under shock load this 1 micron thin surface film is easily disrupted resulting in direct contact between parts. That is why it is so important to have an oil or grease that has the proper extreme pressure (EP) additives to prevent damage to the surfaces under load or shock. Most commodity oils and greases do not have the capability to preserve rolling element contact surfaces under real-world conditions. That is why less than 10% of bearings last for their design life in industrial applications.

If you are interested in improving the life of your bearings, please contact me.